Transmitter

In case of connection of load cells with 4 wires, make a bridge between power supply+ … reference+ and power supply- … reference-

Download installation and usage manual ![]()

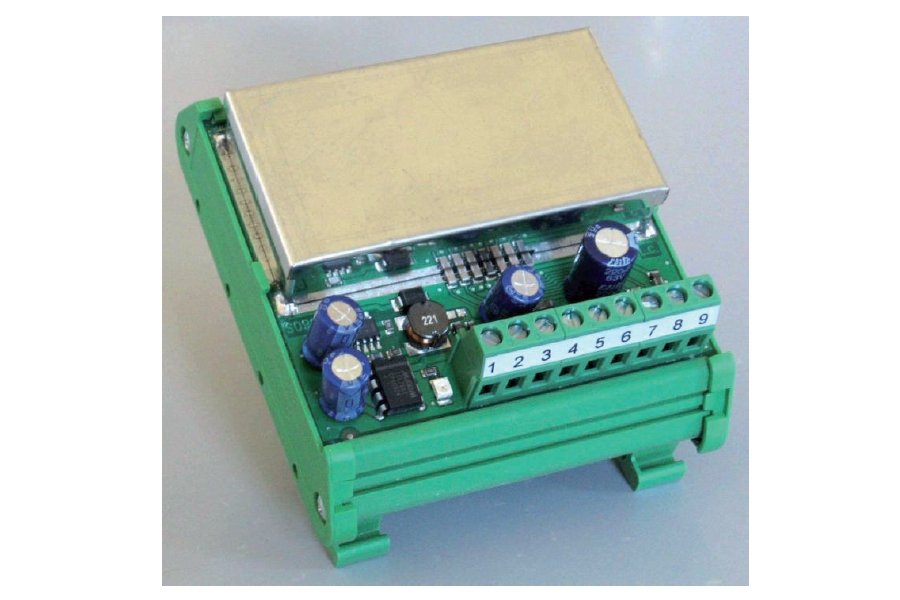

![]() Click to enlarge image

Click to enlarge image

| Power supply | 24 V dc ± 15 % | |

| Max power consumption | 3 W | |

| Isolation | Class III | |

| Operating temperature | -10 / +40°C (14 °F / 104°F) Humidity maximum 85% non-condensing | |

| Storage temperature | -20 / +60 °C | |

| Overall dimensions | 76 x 90 x 65 mm /2.99 x 3.54 x 2.56 in (l x h x p) | |

| Mounting | Support DIN or OMEGA rail | |

| Case material | Polyamide 6.6 UL 94V-0, self-extinguishing | |

| Connections | Removable screw terminals. Pitch screws terminal blocks 5.08 mm | |

| Power supply load cells | 10 V dc / 120 mA (maximum 4 cells with 350 Ω in parallel) short circuit protection | |

| Linearity | 0,02 % of full scale | |

| Temperature deviation | 0,005 % of full scale/°C | |

| Measuring range | 1 mV/V – 2 mV/V – 3 mV/V | |

| Zero / FS Calibration | Adjustment zero & f. s. fine with 18-turn resistive trimmer, zero -8% to +3% f.s.; gain ± 5% f.s. | |

| Analog integrator filter | Adjustable w. single-turn trimmer | |

| Filter response time | 10-90%: 5–250 ms; 4-20mA: 5 ms | |

| Analog output in tension | 0 - 10 V | |

| Impedance | ≥ 10 kΩ | |

| Analog output under current | 0 - 20 mA / 4 - 20 mA | |

| Impedance | ≤ 300 Ω | |

| Conforms to standards | Compliance to EMC norms: EN61000-6-2, EN61000-6-3, Compliance electric safety: EN 61010-1 | |

| Type | Terminal block MA 9P pitch 5.08 |

| Length | ND |

| 1 | +24 Vcc (voltage supply) |

| 2 | GND (voltage supply) |

| 3 | + Exc. Load cell |

| 4 | - Exc. Load cell |

| 5 | - Signal load cell |

| 6 | + signal load cell |

| 7 | Current analog out 0-20mA/4-20mA |

| 8 | - Analog out (current / voltage) |

| 9 | Voltage Analog out 0-10Vcc |

General precautions to be followed in the installation and assembly of load cells: